Biomaster Silver Ion Technology: How It Works, Where It’s Used, and Why It’s Proven

What is Biomaster?

Biomaster is Addmaster’s proven silver ion antimicrobial technology, engineered to provide 24/7 protection against harmful bacteria on treated surfaces. Built directly into products during the manufacturing process, Biomaster delivers permanent, non-leaching, and safe antibacterial performance that lasts the lifetime of the item.

Unlike surface coatings that can wear away over time, Biomaster is incorporated into the material itself. This ensures consistent performance, helping to maintain product hygiene, reduce microbial growth, and extend the usable life of the product.

How Biomaster Works — The Science Behind Silver Ion Technology

Silver Ion Release

When bacteria come into contact with a Biomaster-treated surface, silver ions are gradually released from the additive. These ions are highly reactive and interact directly with microbial cells.

Microbial Cell Disruption

Silver ions bind to bacterial cell walls, penetrating them and disrupting essential functions. This prevents bacteria from growing, reproducing, and forming colonies on the treated surface.

Triple-Action Protection

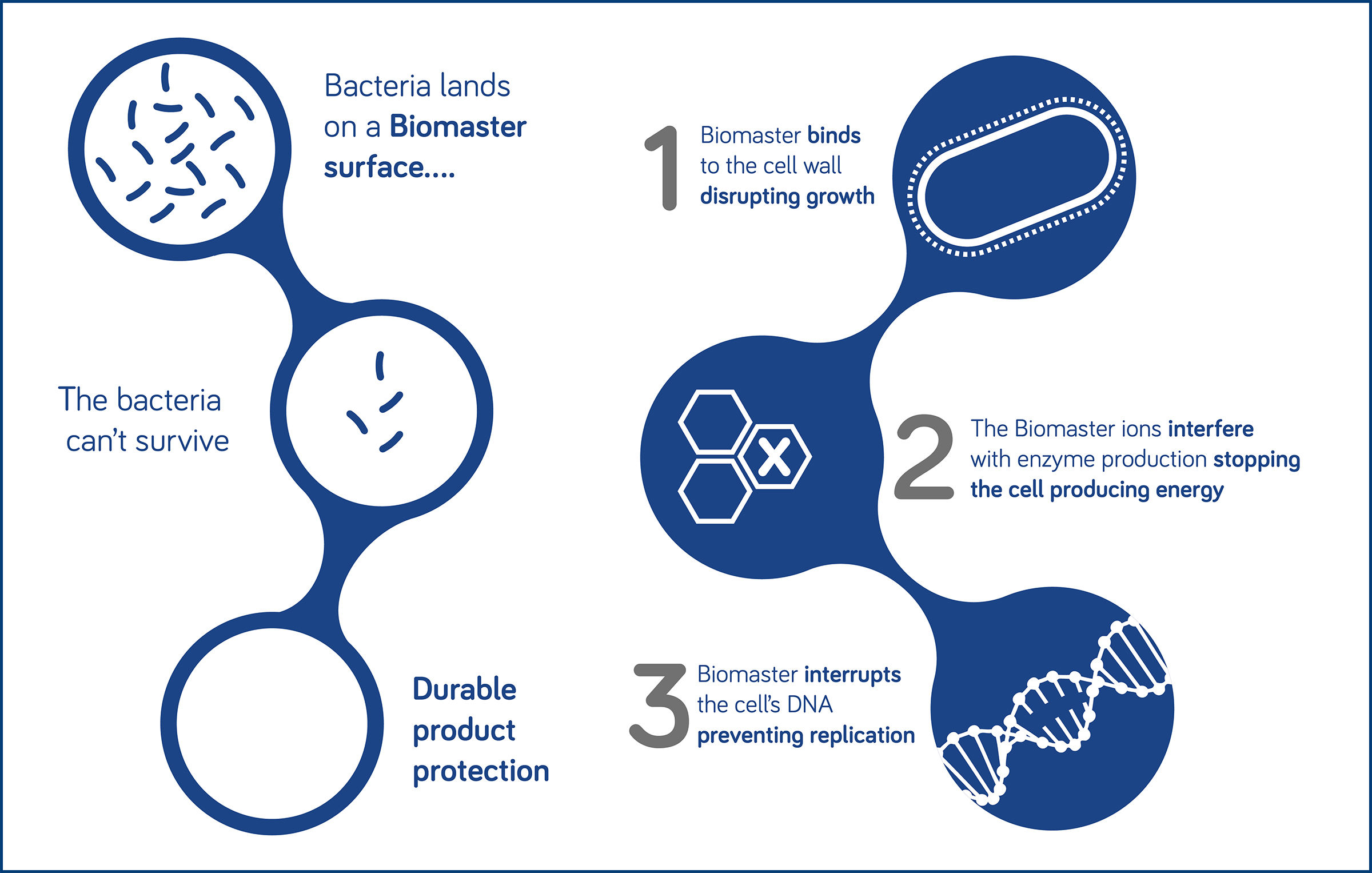

Biomaster works in three complementary ways:

- Blocks enzyme function — Silver ions bind to enzymes in the bacteria, stopping their energy production.

- Prevents DNA replication — Microbes cannot multiply.

- Damages cell membranes — The bacterial cell structure breaks down, leading to cell death.

This continuous, multi-target approach makes it very difficult for bacteria to adapt or develop resistance.

Proven Efficacy — Testing, Compliance, and Standards

Biomaster is independently tested and proven effective against a wide range of bacteria, including E. coli, Staphylococcus aureus, and Listeria monocytogenes.

Key testing and compliance highlights:

- Testing demonstrates significant bacterial reduction on treated surfaces.

- Food contact approved by both FDA and EU regulations.

- Biocompatibility tested to ensure safe use in applications such as medical products.

Laboratory results show that Biomaster-treated surfaces can reduce bacterial growth by up to 99.99%, depending on the application and testing conditions.

Applications Across Industries

Biomaster technology is versatile, making it suitable for a wide range of products and sectors:

Healthcare

- Hospital surfaces and touchpoints

- Medical devices and equipment casings

- Staff uniforms and patient bedding

Food Contact & Catering

- Chopping boards, serving trays, food storage containers

- Food packaging films and conveyor belts

- Commercial kitchen equipment

Sports & Leisure

- Gym equipment grips and touchscreens

- Flooring, mats, and lockers

- Swimming pool changing area surfaces

Transport

- Grab rails and seat backs in buses, trains, and aircraft

- Ticketing machines and payment terminals

Consumer Goods

- Reusable water bottles and coffee cups

- Mobile phone cases, computer keyboards, and remote controls

- Kitchen appliances and utensils

By targeting these diverse sectors, Biomaster helps reduce cross-contamination risk in high-touch environments.

Biomaster vs. Conventional Cleaning

Does Biomaster replace cleaning?

No. Biomaster is designed to work alongside normal hygiene practices — not replace them.

Key differences:

- Cleaning removes dirt, debris, and microbes temporarily.

- Biomaster continuously works between cleaning cycles, reducing the microbial load and lowering the risk of contamination.

This means surfaces are better protected in real-world conditions, especially in environments where constant cleaning is impractical.

Integration into Manufacturing

Biomaster can be easily incorporated into a wide range of materials and products without affecting their appearance or performance.

Delivery formats:

- Masterbatch — Ideal for plastic manufacturing.

- Liquid — Suitable for paints, coatings, and inks.

- Powder — For textiles, paper, and other porous materials.

Compatible materials:

- Plastics and polymers

- Textiles and fabrics

- Coatings, paints, and varnishes

Our technical support team works directly with manufacturers to ensure seamless integration and optimal performance.

Sustainability Benefits

Biomaster doesn’t just improve hygiene — it also supports sustainability goals.

- Extended product life — Reduces material degradation caused by bacterial growth.

- Less waste — Products last longer, reducing the need for replacements.

- Lower chemical use — Reduces reliance on harsh cleaning chemicals, which can be environmentally damaging.

These benefits align with circular economy principles and can help manufacturers meet environmental targets.

Frequently Asked Questions

Is Biomaster safe for food contact surfaces?

Yes. Biomaster is approved for food-contact applications.

How long does Biomaster protection last?

It lasts for the lifetime of the product — it cannot be washed off or worn away.

Does Biomaster work against viruses?

Biomaster is primarily designed to reduce bacterial growth. Separate testing is required for viral efficacy.

Can Biomaster be added to recycled plastics?

Yes. Our technical team can help ensure performance when using recycled materials.

Conclusion

Whether you manufacture medical equipment, consumer goods, or industrial products, Biomaster silver ion technology offers a proven, permanent solution for improving hygiene and reducing bacterial growth. Independently tested, regulatory-compliant, and easy to integrate, Biomaster gives your products a clear performance advantage.

Contact Addmaster today to learn how Biomaster can be incorporated into your next project.

What Next?

🔗 Follow us on Social Media, here is our LINK TREE

✉️ See how our additive technology can benefit your business by CONTACTING US

🦠 Find out more about Biomaster Antimicrobial Technology HERE

🎥 Watch our video on how Biomaster works WATCH NOW

📰 Subscribe to our Newsletter - SUBSCRIBE

← Back to blog